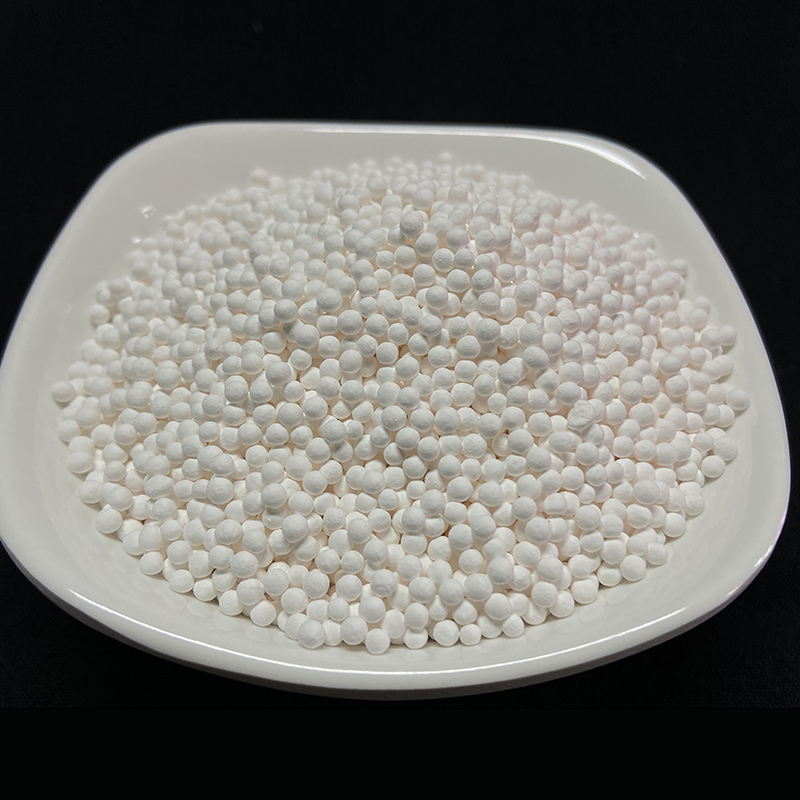

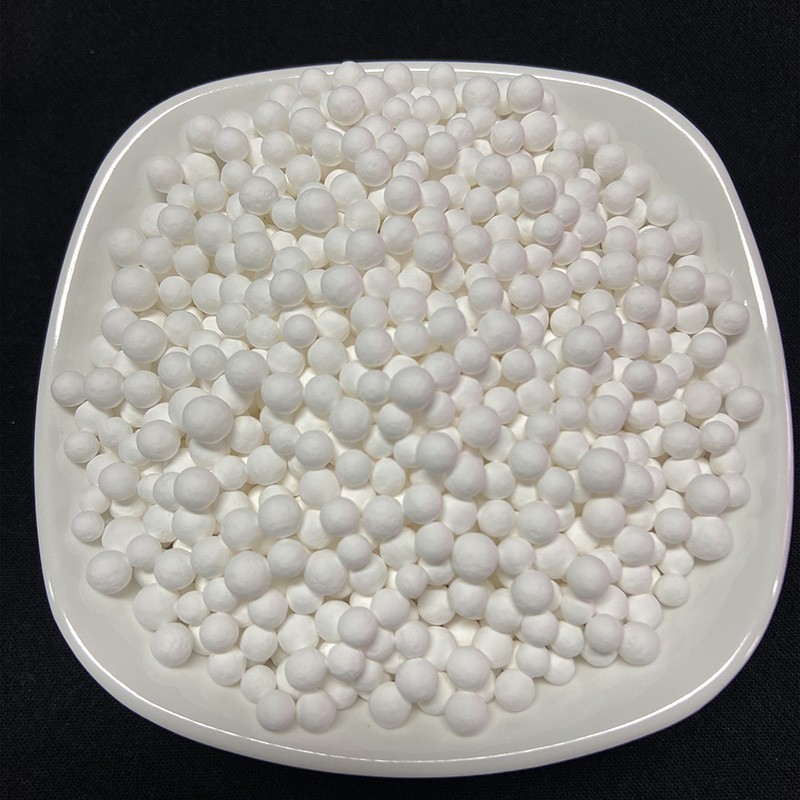

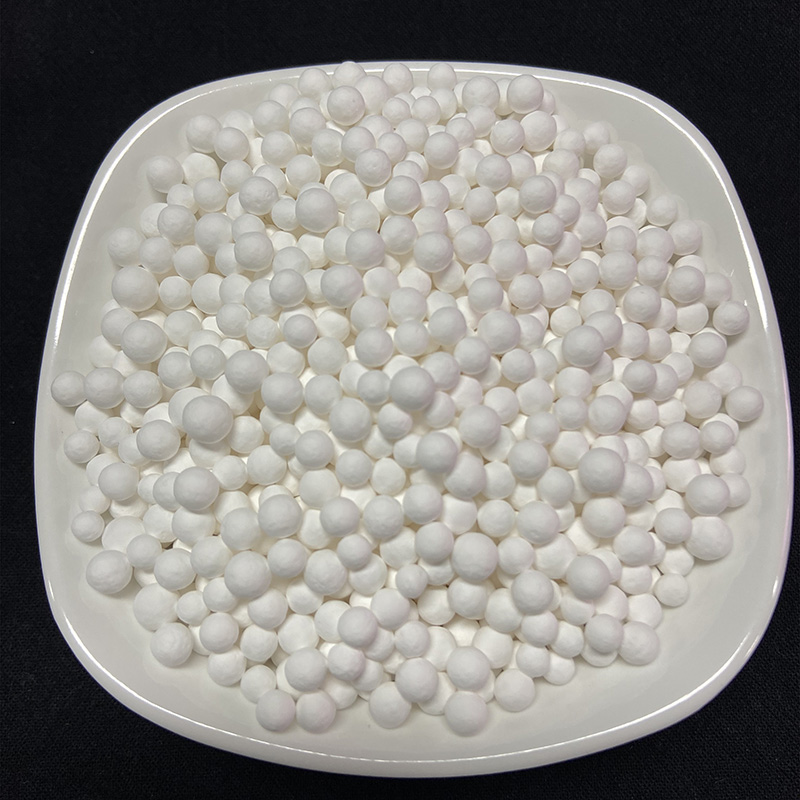

Alumina keramyske filler Hege aluminiumoxide inerte bal / 99% aluminiumoxide keramyske bal

Fysyske en gemyske eigenskippen fan inerte keramyske ballen

| Fysyske en gemyske eigenskippen fan inerte keramyske ballen | |||||||

| Elemint | Al2O3% | 60 | 70 | 80 | 90 | 95 | 99 |

| Fe2O3% | ≤0.9 | ≤0.8 | ≤0.6 | ≤0.4 | ≤0.3 | ≤0.1 | |

| De oerbleaune komponinten kinne bepaald wurde troch ûnderhanneling tusken de leveransier en de keaper as it nedich is. | |||||||

| wetterabsorpsje, % | 3 ± 1, It kin ek bepaald wurde troch ûnderhanneling tusken de leveransier en de keaper | ||||||

| oanpart, kg/m³ | 2.5-3.0 | 2.7-3.2 | 2.9-3.2 | ≥3.1 | ≥3.2 | ≥3.4 | |

| Bulkdichtheid, kg/m³ | 1400-1550 | 1400-1650 | 1500-1800 | 1700-1950 | 1800-1950 | ≥1900 | |

| Stof, barst of brek | In inkele tas is minder as 5% | ||||||

| Grutte ôfwiking | Uniforme sfear, de ferhâlding fan 'e grutste oant de lytste diameter fan in keramyske sfear is net mear as 1.2 | ||||||

| Dimensjonele tolerânsje | ≤10mm | ±1.0 | |||||

| 11—25mm | ±1.5 | ||||||

| 26—50mm | ±2.0 | ||||||

| ≥50mm | ±3.0 | ||||||

| Frije falsterkte | Ferliesleaze taryf ≥99% | ||||||

| Kompresjesterkte | φ3 | ≥250 | ≥300 | ≥350 | ≥400 | ≥500 | ≥500 |

| φ6 | ≥800 | ≥1000 | ≥1000 | ≥1200 | ≥1500 | ≥1500 | |

| φ8 | ≥1500 | ≥1600 | ≥1800 | ≥2000 | ≥2500 | ≥2500 | |

| φ10 | ≥2000 | ≥2500 | ≥2800 | ≥3000 | ≥3500 | ≥3500 | |

| φ13 | ≥3000 | ≥3000 | ≥3500 | ≥4000 | ≥5000 | ≥5000 | |

| φ16 | ≥3500 | ≥4000 | ≥4500 | ≥5000 | ≥6000 | ≥7000 | |

| φ20 | ≥6000 | ≥6000 | ≥7000 | ≥8000 | ≥10000 | ≥12000 | |

| φ25 | ≥7000 | ≥7000 | ≥8000 | ≥10000 | ≥15000 | ≥17000 | |

| φ30 | ≥8000 | ≥9000 | ≥10000 | ≥12000 | ≥17000 | ≥19000 | |

| φ38 | ≥10000 | ≥12000 | ≥13000 | ≥15000 | ≥20000 | ≥22000 | |

| φ50 | ≥12000 | ≥14000 | ≥16000 | ≥18000 | ≥22000 | ≥26000 | |

| φ75 | ≥16000 | ≥18000 | ≥20000 | ≥22000 | ≥25000 | ≥30000 | |

| 50-75 | 55-75 | 60-80 | ≥80 | ≥82 | ≥85 | ||

| Slijtagepersintaazje % | ≤2 | ≤1 | |||||

| soere oplosberens, % | ≤6 | ||||||

| Alkaliniteit, % | ≥77 | ≥85 | ≥90 | ≥92 | ≥95 | ≥97 | |

| Refraktiviteit, ℃ | ≥400 | ≥500 | ≥700 | ≥1000 | ≥1000 | ≥1000 | |

| Bestindich tsjin hommelse drukferskillen | Net-destruktive taryf ≥ 99%, gjin feroaring yn kompresjesterkte en druk nei hommelse feroaring is minder as 25% | ||||||

| Bestindich tsjin hommelse temperatuerferoaringen | Ferliesleaze taryf ≥99% | ||||||

| Pakket | Ferpakking fan izeren trommels | Ynpakt yn izeren trommels, fersegele mei dikke PP- of PE-plestik tassen | |||||

| Ferpakking fan woven tassen | Beskikber yn stevige en UV-bestindige woven tassen | ||||||

| Opmerking: Gegevens oer bulkdichtheid binne allinich foar referinsje, net as basis foar akseptaasje. | |||||||

In oare opmerking: Sjoch tabel 5 foar de wetteropname fan 99 fillerballen

| 99 Foljende bal wetterabsorpsje | ||

| 99 filler | diameter | diameter |

| rolfoarmjen | φ<25mm | <5% |

| Masinepersfoarmjen | φ>25mm | <10% |

99,5% Technyske Yndikatoaren

| Al2O3 | ≥99% |

| SiO2 | ≤0,14% |

| Fe2O3 | ≤0,04% |

| CaO + MgO | ≤0,03% |

| TiO2 | ≤0,06% |

| Na2O | ≤0,1% |

| K2O | ≤0,1% |

Fysike yndeks fan gemyske fillerbal

| BETINGST | YNDEKS |

| ladingfersêfting (yb/t370-1995) | Deformaasje ûnder 0.2mpa druk is minder as 0.6% |

| Termyske skokbestindichheid (yb/t376.2-1995) | 1200°C oant 600°C. 10 kear sûnder oerflakbarsten |

| Wizigingen yn 'e opnij brânende line (gb/t3997.1-1998) | 1400 ℃ foar 12 oeren, de maksimale wearde is 0,25%, de gemiddelde wearde is minder as 0,20% |

| Bulkdichtheid (gb/t2997-2000) | 3,2-3,50 g/cm³3 |

| ferpletterjende krêft | Foldocht oan mear as 230 kg/cm2 |

| Skynbere porositeit | 12-18% |

| Bulkdichtheid | 2,1-2,3 g/cm³3 |

Gemyske ferpakking balferpakking

1) Gewoane ferpakking: polyetyleen woven tas mei nettogewicht fan 25 kg, plus pallet

2) Ferpakking fan stielen trommels: 100L ferpakking fan stielen trommels, pallets kinne tafoege wurde